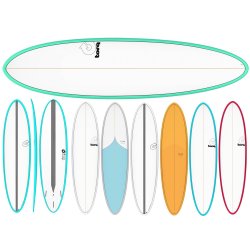

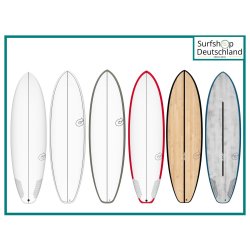

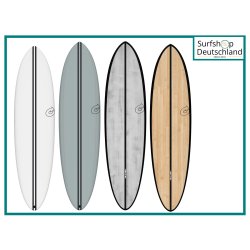

TORQ Surfboards, the brand founded in 2012, created a new standard in the epoxy surfboard market and offer an unmatched combination of durability and performance not only in europe. Buy these great TORQ surfboards online in our surf shop. For this year, innovation continues with new surfboard shapes, new graphics, a new collaboration with Channel Island Surfboards and the introduction of the world's first EPS/Epoxy pre-preg surfboard. The Torq range now offers 5 types of Surfboard technology for all skill levels.We offer you all shapes and builds in different sizes. Check it out.

History of the Torq Surfboards

Torq Surfboards, based in Portugal, was founded in 2012 by Sebastian Wenzel in Germany. Through cooperations with Channel Island, the product portfolio was expanded again. The distribution was distributed by the ISA (International Surf Alliance) on seven shoulders (companies), so that the distribution is guaranteed worldwide.

Torq Surfboards - exciting collaborations- durable and sustainable.

Torq surfboards are made using CNC machined aluminum molds. to eliminate waste and produce uniformly shaped surfboards. These that are durable, have good flex and are offered at an affordable price. Torq is the brainchild of longtime windsurf shaper Sebastian Wenzel and is distributed worldwide through a network of international surf distributors (International Surf Alliance). Following a successful collaboration with Channel Islands, Torq continues to expand its business.

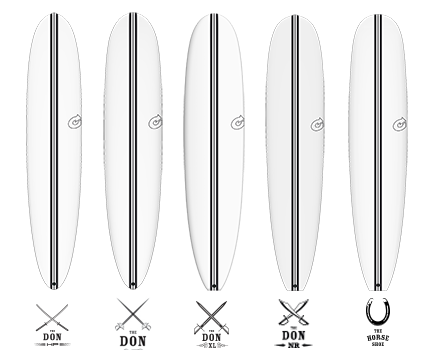

How successful is the cooperation between Torq Surfboards and Channel Islands?

The collaboration between Torq Surfboards and Channel Islands Surfboards is a great success story. The interest of the PodMod and Chancho models meets great interest all over the world. an With the new X-lite Layup, Torq is able to offer a light and very durable surfboard with good flex at a very good price. There may be more Torq Surfboards collaborations in the future, but for now Torq is very happy with the Channel Islands partnership.

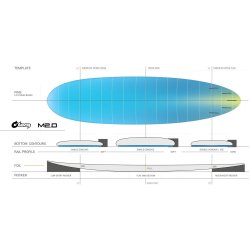

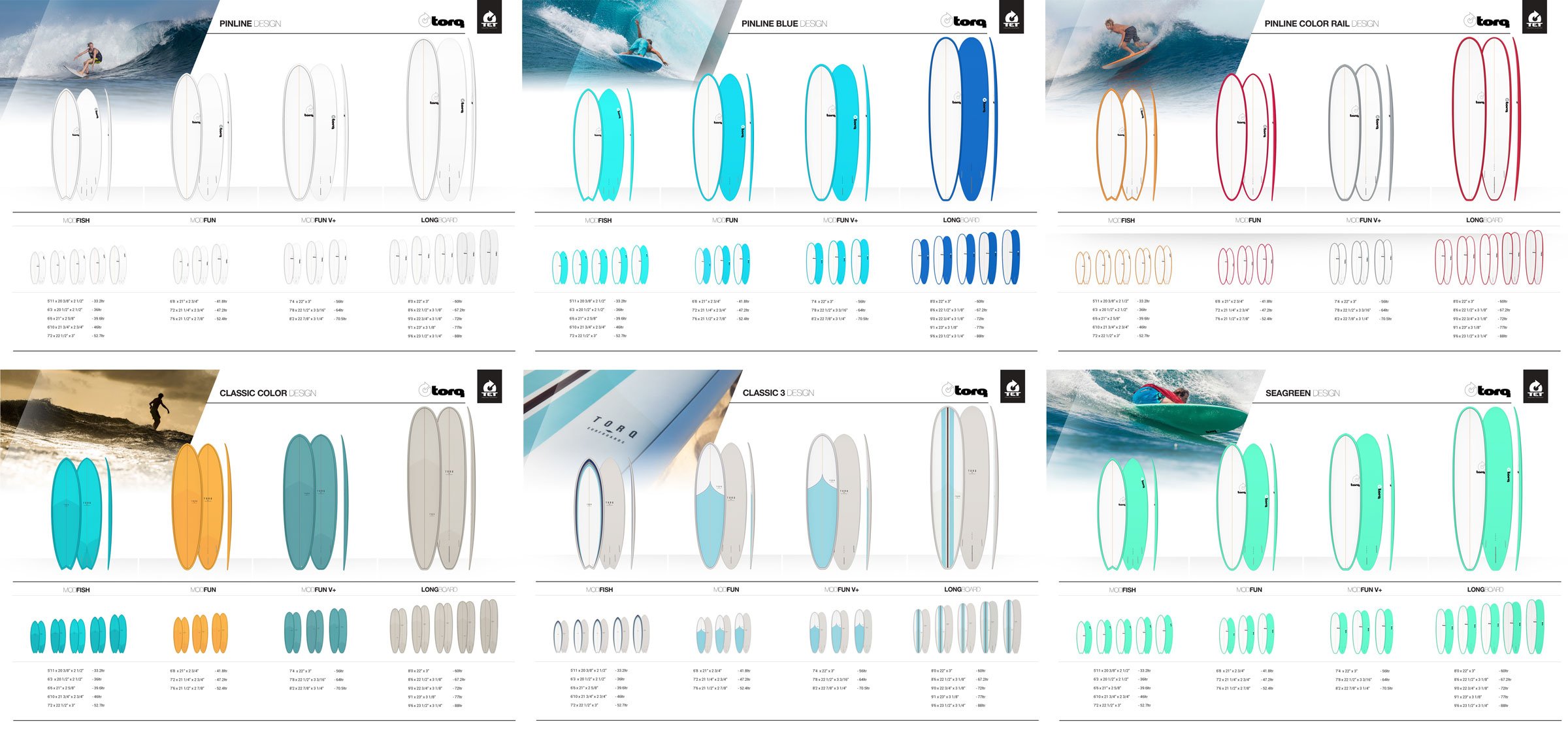

TORQ Surfboard Technologys

We at Hang Loose Surfshop would like to introduce you to the different construction designs of the TORQ surfboards. We shed light on the dark barrel and explain the differences and advantages of each construction.

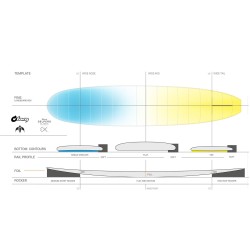

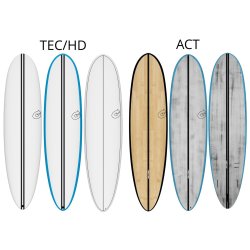

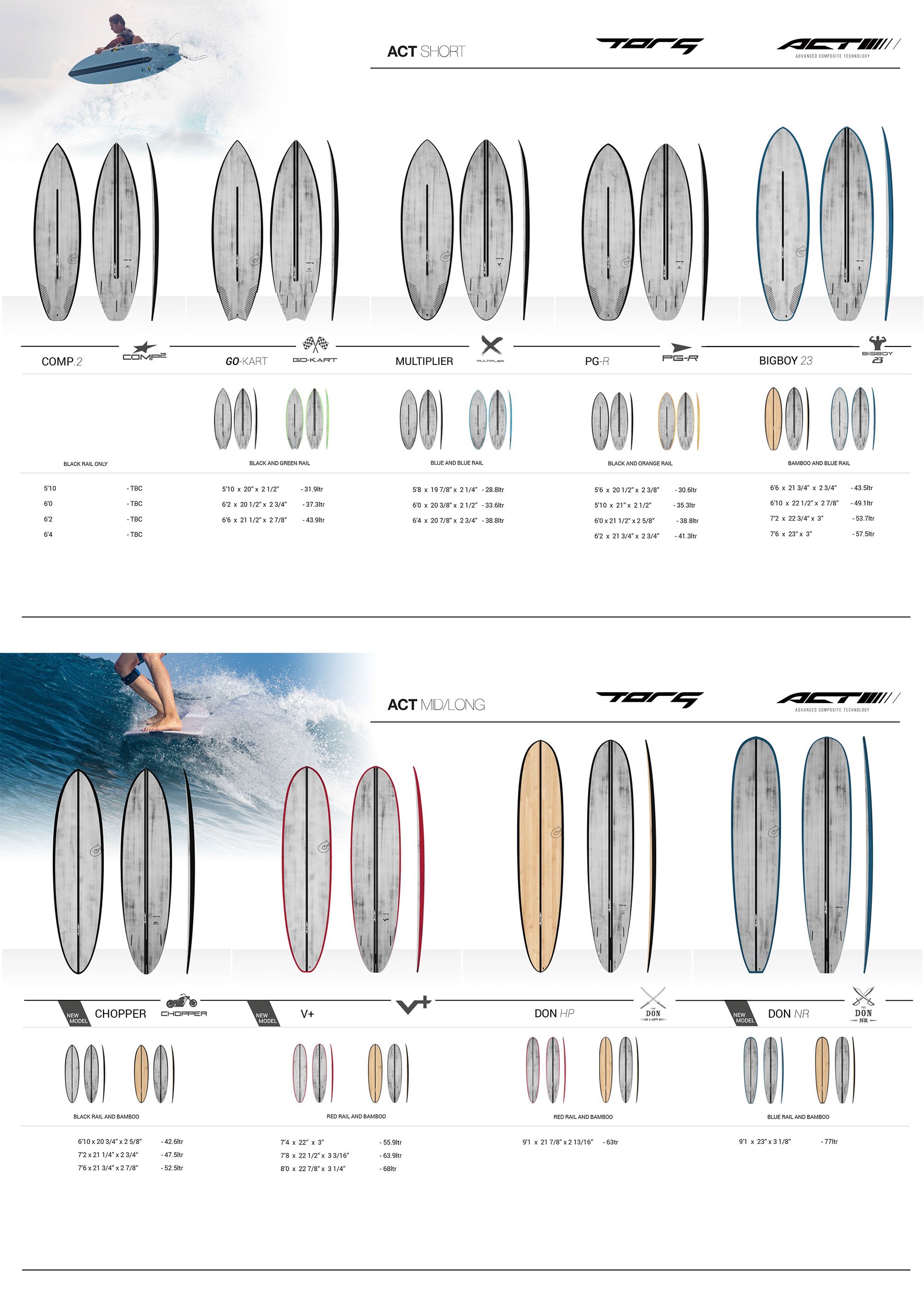

ACT - Torq Surfboard Technology

For the ACT Torq Surfboard Technology Boards there is only one name. Absolute High Perfromance!

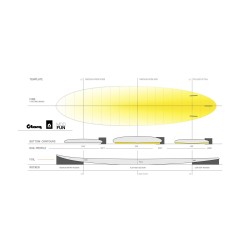

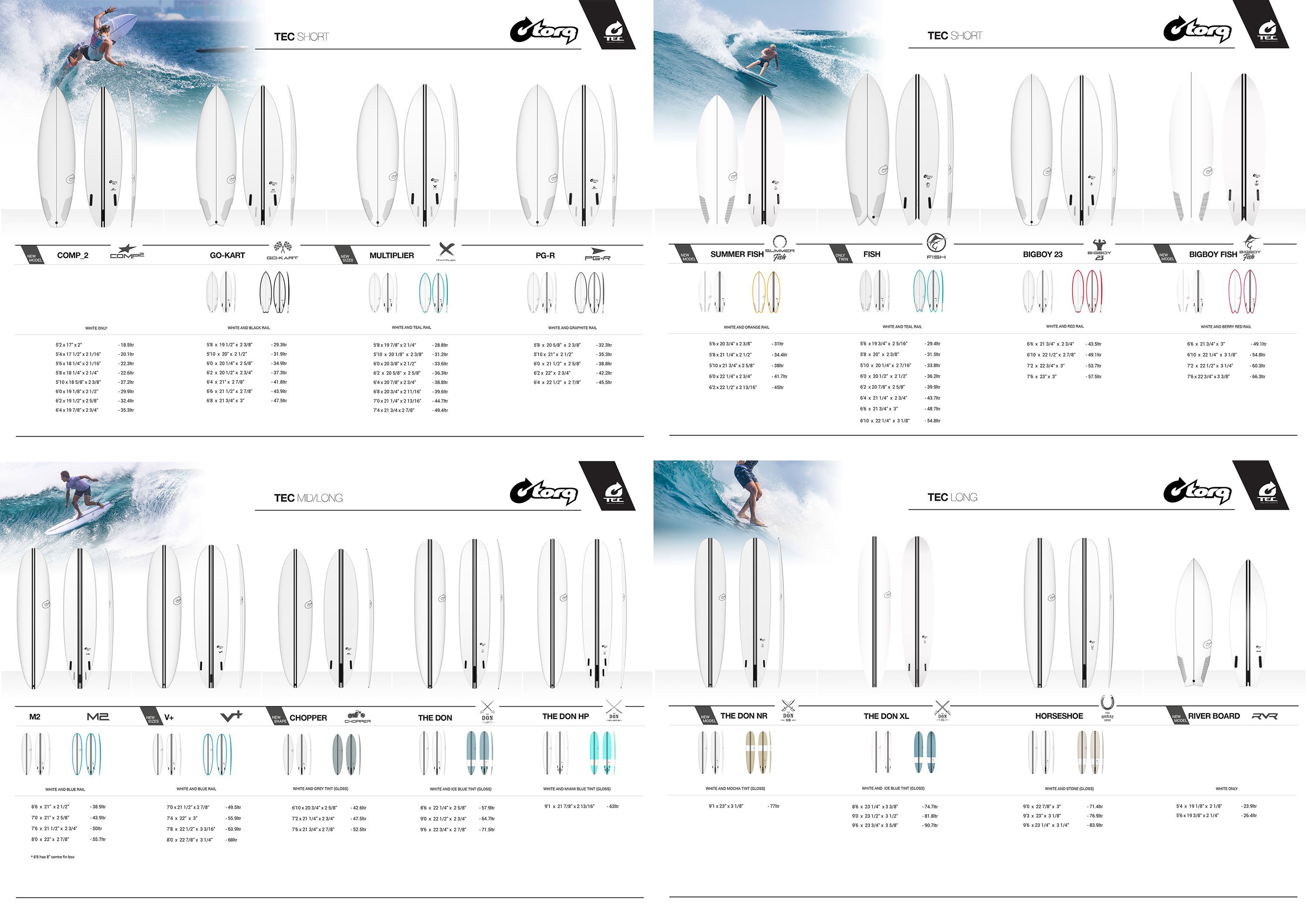

TEC - Torq Surfboard Technology

The TEC Torq surfboard technology is made with a special vacuum. For more information, visit the TEC TECH page.

X-Lite - Torq & Channel Islands Surfboard Technology

The X-Lite Torq Surfboard Technology is realized in a cooperation with Channel Island Surfboards. For more information please visit the X-Lite TECH page.

.jpg)

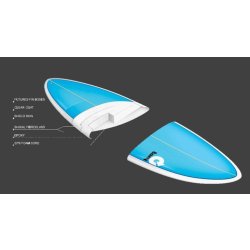

TET CS- Torq Surfboard Technology

The TET CS Torq Surfboard Technology is slightly lighter than the TET Technology. The thinner glassing is compensated with a carbon stringer patch. For more information please visit the TET CS TECH page.

TET - Torq Surfboard Technology

The TET Torq Surfboard Technology is the most durable surfboard construction. For more information, please visit the TET TECH page.

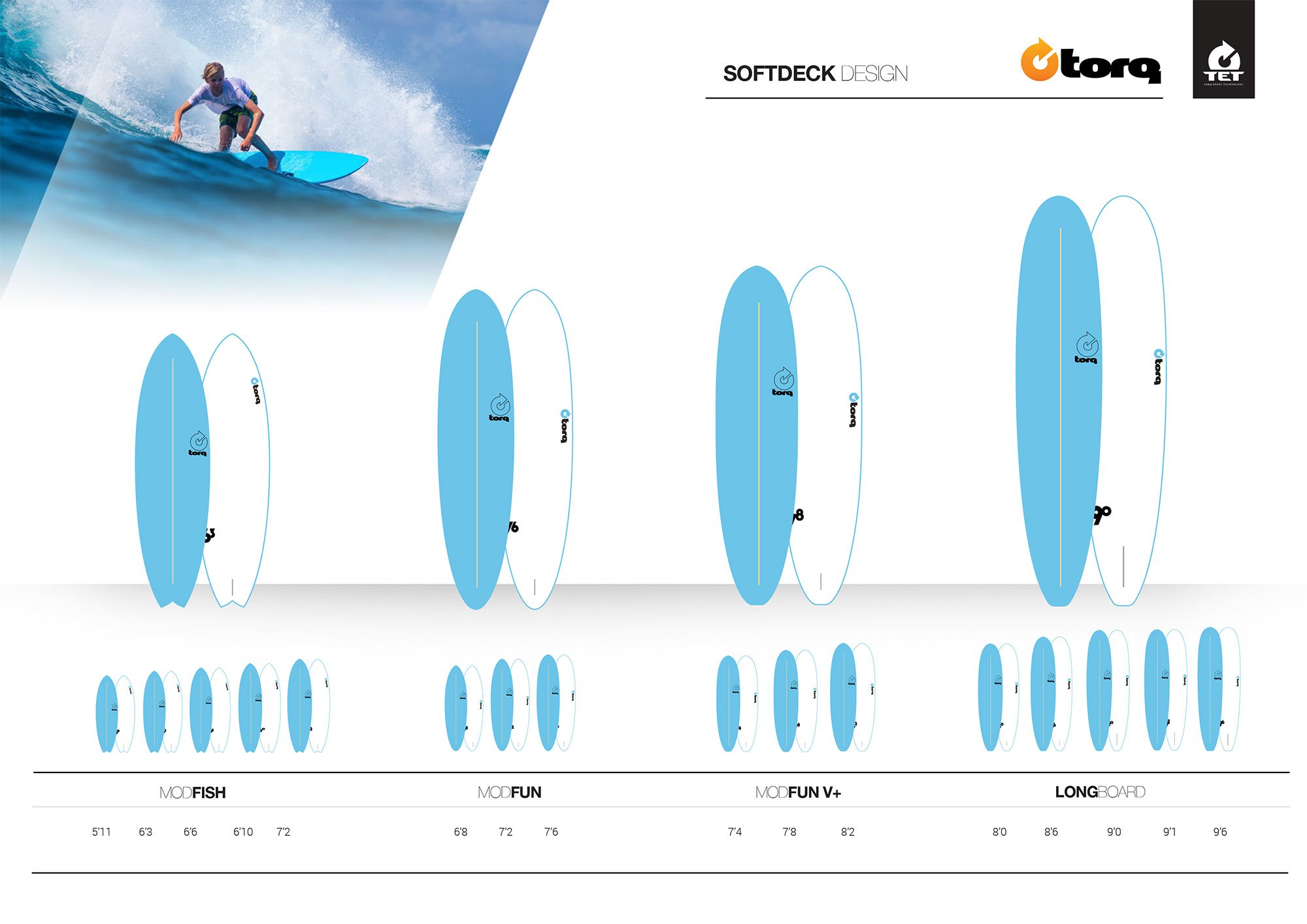

SoftDeck - Torq Surfboard Technology

The Torq Softboard Surfboard Technology is perfect for beginners and to prevent injuries. For more information, please visit the SOFT TECH page.

Torq Surfboards and Sustainability

The Torq Surfboards brand was founded on a new and revolutionary method of making surfboards with perfect precision and virtually no waste. From day one, the goal has been to make Torq surfboards the most efficient, cleanest and waste-free product that can be manufactured.

After all, surfboards are a product made of various materials that are currently neither recyclable nor biodegradable. Every board we buy has an impact on our environment. The lifespan of the surfboard ultimately determines the amount of waste it generates. The claim that a surfboard is sustainable or environmentally friendly can be extremely misleading. This must be properly explained and justified, with an overview of the total impact during the production and life of the product.

LOW WASTE:

Torq Surfboards makes boards differently than any other manufacturer.

The original Torq surfboards - the TET, TET-CS and X-Lite - were designed using a new manufacturing method. An EPS blank is blown into a mold with no mold waste, then wrapped with biaxial fabric, the scraps are removed after drying and recycled with other glass. The resin is metered by computer and applied in a molding system that produces no resin waste. The molded surfboard requires minimal finishing - no extensive sanding or cleaning of tools such as brushes and squeegees with environmentally harmful acetone or chemicals such as cellulose.

Energy for the molding process comes from a 700-kW solar array on the Torq Surfboard manufacturing site.

This is the cleanest and lowest-waste process currently used in surfboard production. For detailed information, please visit our technology pages.

SOURCED FROM THE REGION

Our blanks are manufactured close to the TET production facility. Fins and fin boxes are also manufactured nearby (using a mold approved by Futures Fin), and the resin is sourced within 100 km.

RECYCLED

Unlike traditional surfboard manufacturing processes where the resin and fabric are combined before the excess is removed, creating a non-recyclable waste, our fiberglass fabric is dry laid and the excess is removed before the resin is applied. The excess fabric is recycled like normal material.

RENEWABLE ENERGY

The energy for our casting process comes from a 700 kW solar plant on our production site.

HIGH QUALITY MATERIALS:

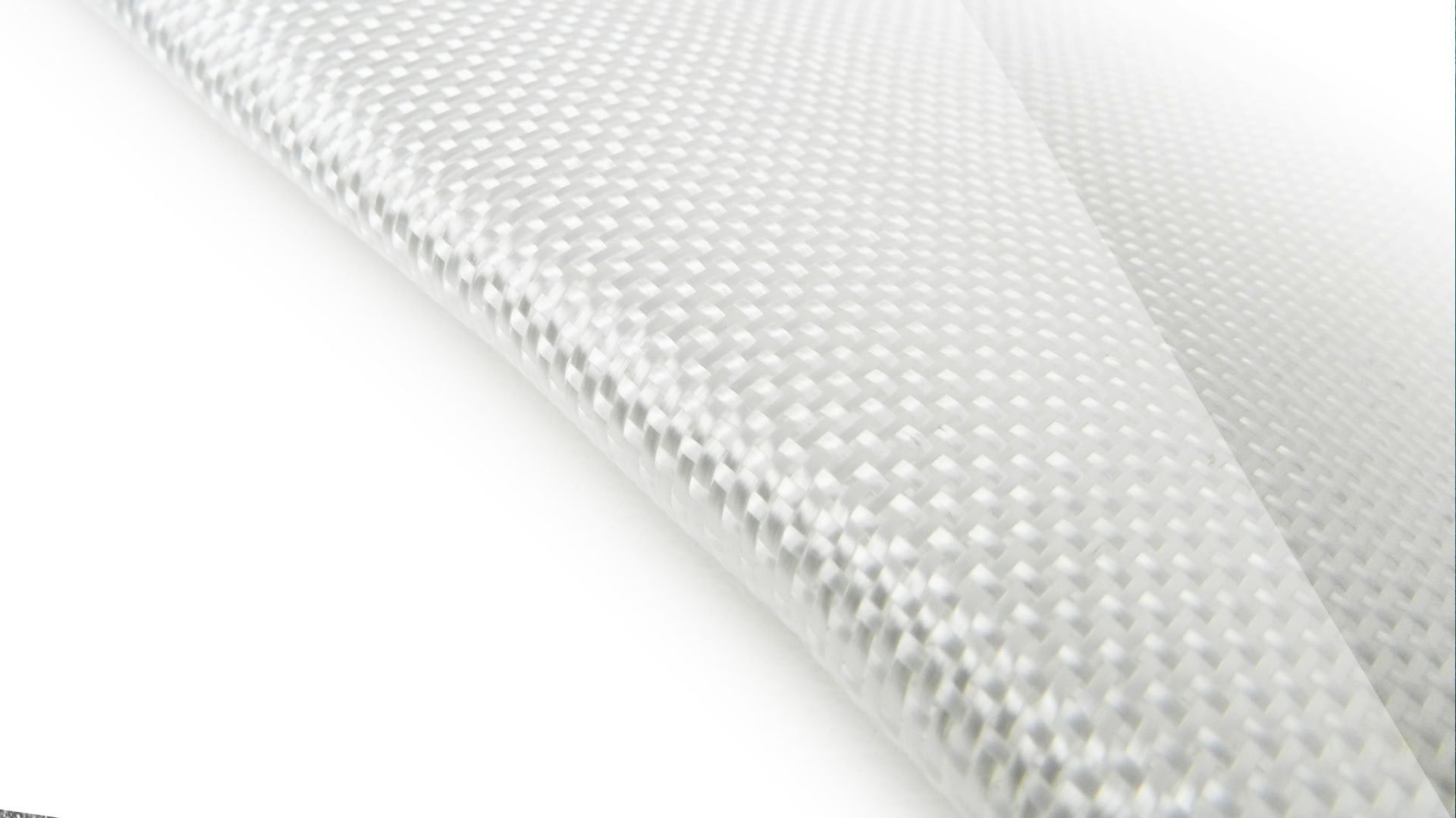

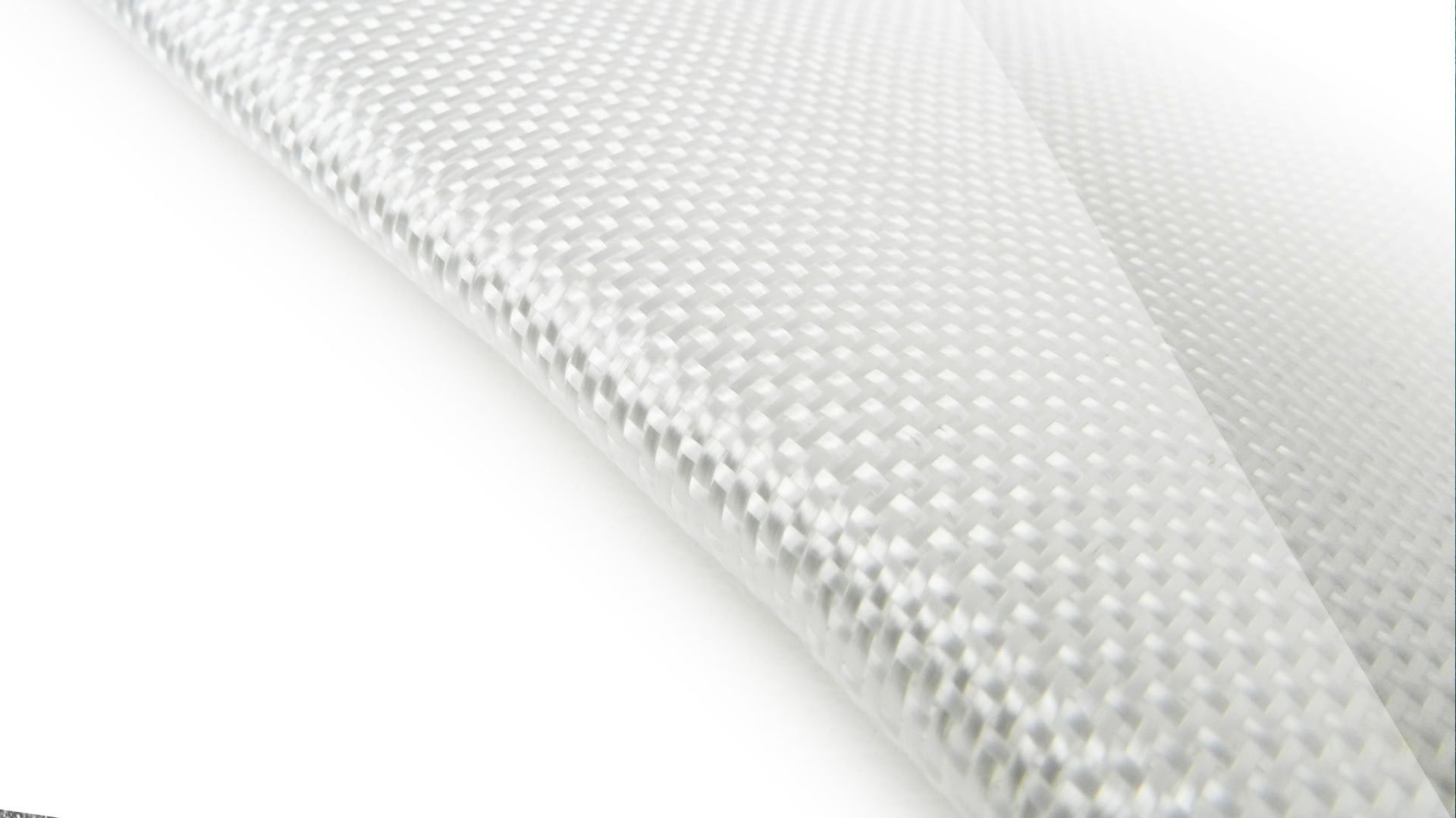

Biaxial fiberglass

Bi-directional fiberglass has extremely high strength and torsional stiffness, making TET, TET-CS and X-Lite boards some of the strongest surfboards on the market.

The unique lay-up and forming process means that offcuts can be recycled.

Plain Weave Fiber

TEC and ACT use a standard canvas fiber, but in much larger numbers. The industry standard is usually 2 x 4 oz or 4 oz + 6 oz on the deck and a single 4 oz or 6 oz on the base. Torq surfboards use an additional 6 oz deck and an additional 4 oz or 6 oz for the base, double the amount of fiber.

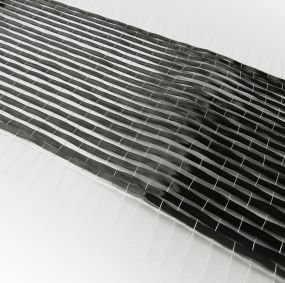

Carbon Fiber

For TET-CS, X-Lite, TEC and ACT we use a unidirectional carbon fiber. This is not woven and is therefore stronger than carbon fabric.

These are real carbon strands, not just tape or paper transfers as sometimes used for aesthetic reasons. This gives the boards more stiffness and strength.

EPS Foam

Torq only makes surfboards with EPS foam and epoxy resin.

The EPS used by Torq Surfboards is a high density, blown model that uses only steam to expand the beads and blow the blank. This is much better than polyurethane foam, which releases toxic MDI and TDI when the blank is blown.

Epoxy Resin

Stronger than polyester resin and with significantly less VOCs (volatile organic compounds).

Torq Surfboards tests bio-based resins to find the best balance between low waste production and durability.

Components

Torq Surfboards produce Futures finboxes themselves with a license granted by future Fins in a single injection molding machine. This avoids the need for shipping.

TORQ SURFBOARDS BUILDS STABLE BOARDS

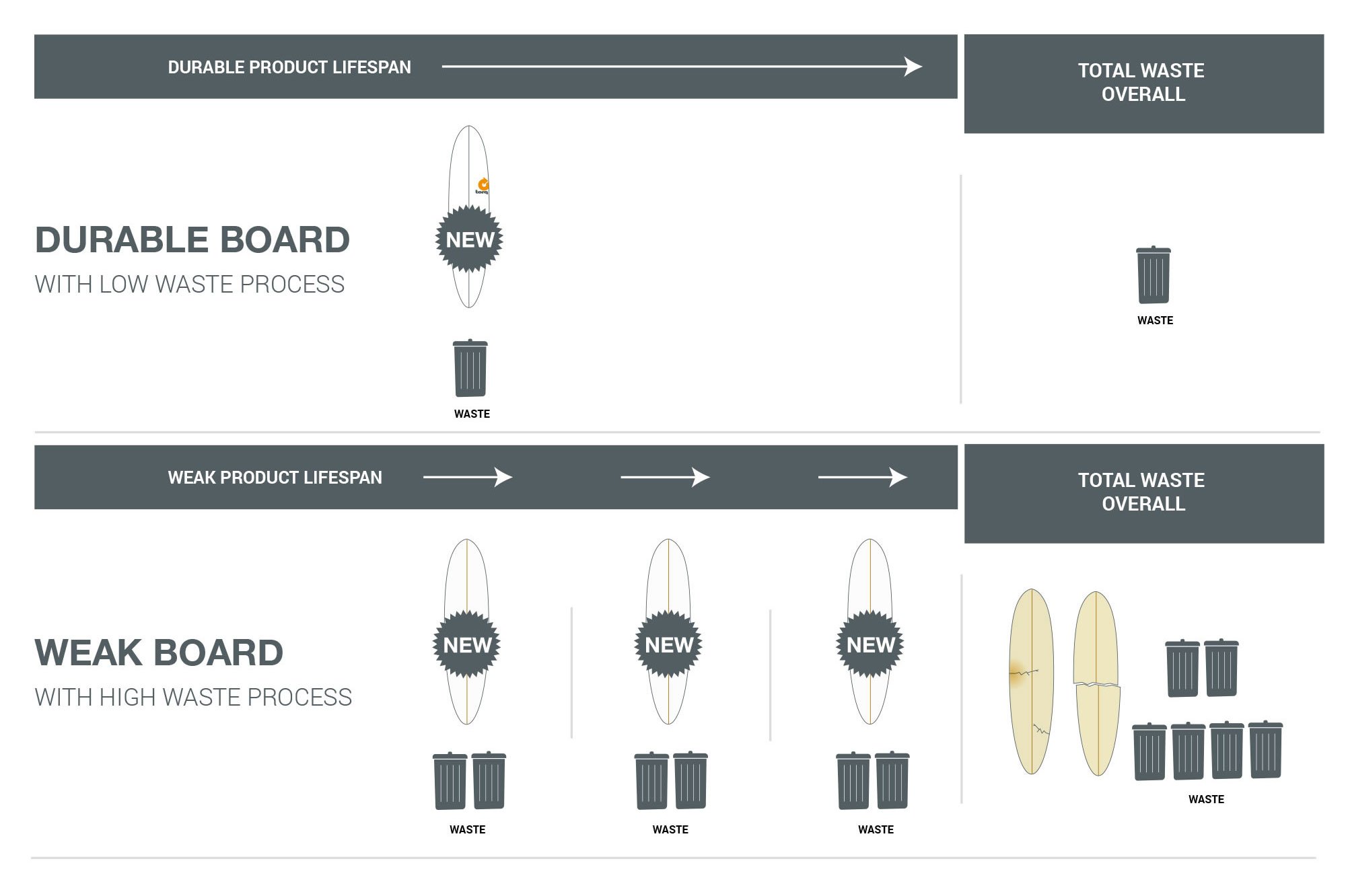

The most overlooked and under marketed part of sustainability in surfboards is durability. A lightweight board with only a few layers of 4 oz fiberglass is a true waste bomb just waiting to be discarded. The most sustainable surfboard is the one that lasts the longest.

Torq Surfboards has tested its technologies for over a decade and each new technology is thoroughly tested.

All of our boards are rated for durability in the Torq Tech Compass, which can be found on our website for each board.

LONGEVITY/LOW-WASTE EFFECT

The combination of durability AND low waste is critical to overall sustainability.

Every new board leaves a footprint: material waste, energy consumption and ultimately the board itself. A weak surfboard , which needs to be replaced every year, multiplies the overall footprint, whereas a durable and low-waste surfboard has a much smaller impact over time.

ENVIRONMENTALLY FRIENDLY SHIPPING

Shipping is a two-sided problem. The manufacturer of a surfboard has to transport all the individual parts - blanks, fiberglass, resin, leash cups, fin boxes, as well as brushes, scrapers, abrasives, cleaning chemicals, and so on. And then the finished board is delivered to the store or customer.

Torq surfboard production is located near all suppliers, and in some cases TORQ manufactures the parts themselves, so Torq only need to ship the finished product and not the unfinished parts. And the Torq Surfboards low-waste process means that the waste elements are not shipped with the raw materials.

TORQ Surfboards are packaged plastic-free with paper and tape and shipped in custom-fit, bleach-free boxes.

The brand Torq Surfboards was founded in 2012 in the Germany.

TORQ Surfbards was founded in Germany in 2012 by Sebastian Wenzel in cooperation with the newly formed ISA (International Surf Alliance).

Torq surfboards are produced in Southeast Asia.

Sebastian Wenzel is the CEO of Torq Surfboards. He has 35 years of experience in windsurf board manufacturing, is a professional windsurfer and still designs shapes for Fanatic. He is also the former Global Brand Manager of NSP Surfboards.

The idea Torq Surfboards, was developed by Sebastian Wenzel in 2010. Following his idea, he gathered a group of international surf distributors and they decided to join forces. The ISA - International Surf Alliance was born. With a global network, ISA started developing the Torq Surfboard brand.

ISA is a company owned by seven shareholders, each of whom distributes Torq surfboards in their respective territories. The ISA shareholders are in close contact with the brand and are involved in all important decisions.

.jpg)